Custom End Mills for Your Application

Blueswin delivers custom end mills and precision cutting tools tailored to your material, geometry, and machining requirements—for cleaner cuts, longer tool life, and consistent performance.

- South China’s leading end mill manufacturer

- PhD-led team + world-class precision equipment

- 1,000+ CNC machines across 20,000㎡ factory

- Specialists in complex geometries & tough materials

- Fast custom solutions. Delivered on time

Precision Machining Starts with Custom End Mills

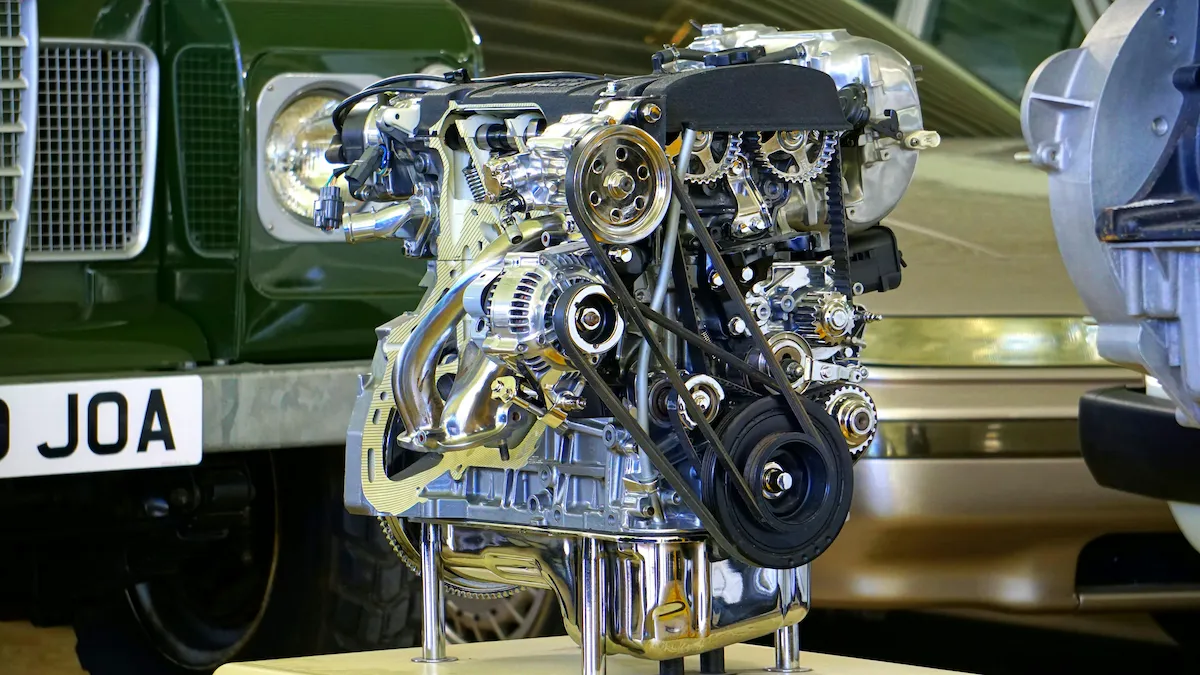

Automotive & EV

Precision tooling for high-speed, lightweight manufacturing

- Custom end mills for engine blocks, gear housings, battery components

- Lightweight tooling for aluminum and magnesium alloys

- Optimized geometries for surface finish and chip evacuation

Automotive and electric vehicle manufacturers require tools that deliver unmatched speed, durability, and precision. At Blueswin, our custom end mills are engineered to excel, optimizing the machining of critical components like engine blocks, transmission casings, battery enclosures, and structural aluminum parts. With advanced geometries, our tools ensure superior chip evacuation, impeccable surface finishes, and extended tool life, even in high-speed automated production lines. Whether prototyping lightweight magnesium alloy parts or scaling up to produce thousands of aluminum housings weekly, Blueswin empowers seamless R&D and high-volume manufacturing with consistent, reliable performance. Partner with us to reduce cycle times, minimize tool changes, and elevate your production efficiency—driving your success with precision-engineered solutions.

From wear-resistant coatings for high-volume production to ultra-fine finishing tools for complex contours, our capabilities give you the flexibility to tackle diverse materials—steel, copper, plastics, or hardened alloys—with consistent quality and confidence.

Aerospace & Aviation

Engineered for advanced materials and critical tolerances

- Composite cutting tools for carbon fiber and CFRP panels

- Machined parts for airframes, turbines, and avionics housings

- High-precision, low-wear performance for titanium and Inconel

Aerospace machining tackles the toughest materials—titanium, Inconel, carbon fiber composites (CFRP), and aluminum alloys—each demanding specialized tool strategies. At Blueswin, our custom end mills are precision-engineered for critical applications, from structural airframes and engine components to turbine blades and avionics housings. Featuring advanced heat-resistant coatings, optimized high-flute geometries, and reduced cutting forces, our tools deliver flawless edge quality, prevent delamination in layered composites, and excel in high-stakes environments, ensuring unmatched performance and reliability.

Our tools empower aerospace manufacturers to achieve tight tolerances, exceptional dimensional repeatability, and extended tool life, meeting the industry’s rigorous standards with ease. From intricate turbine details to robust airframe skeletons, Blueswin’s solutions enhance efficiency, reduce production downtime, and drive superior results. Partner with us to elevate your machining process and soar above the competition with tools designed for aerospace excellence.

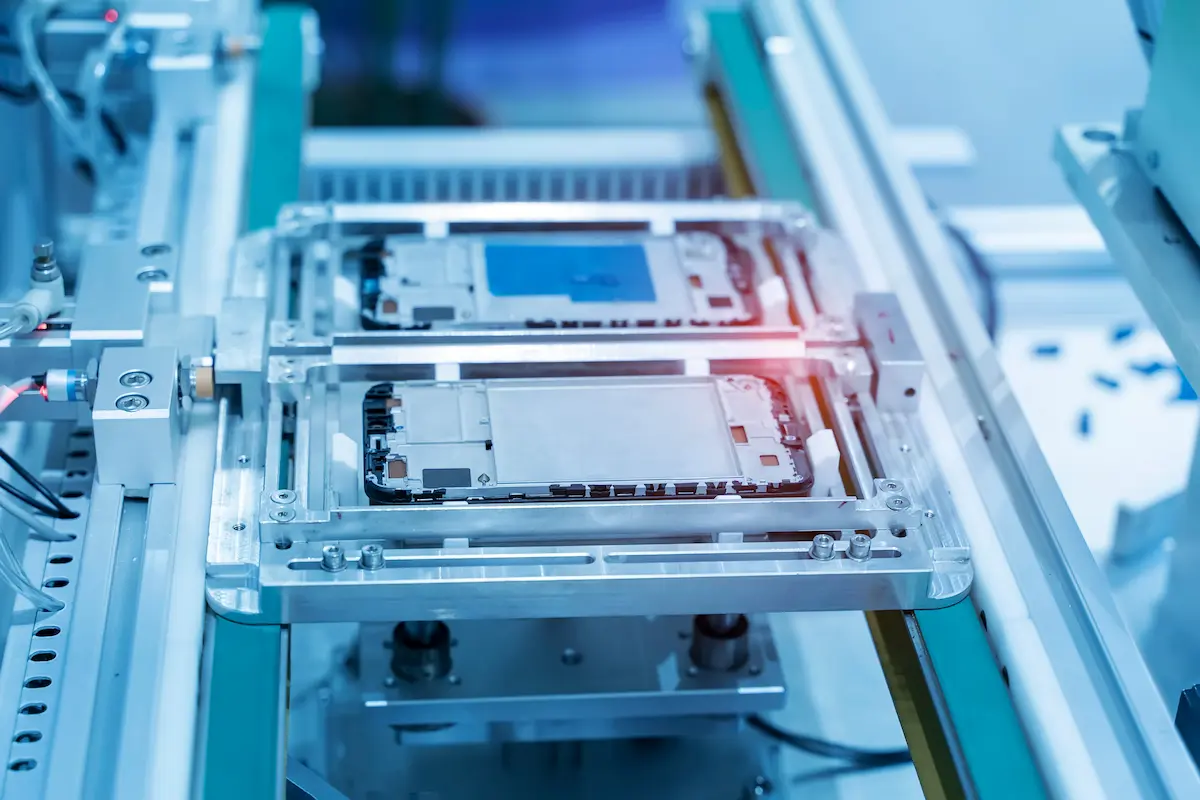

Consumer Electronics & Display

Micro-precision tools for high-volume, high-accuracy production

- End mills designed for cutting polarizing films and metal enclosures

- Ultra-small diameters with tight concentricity

- Surface-sensitive edge profiles to reduce material stress

In electronics manufacturing, even minor tool deviation can lead to major quality issues. Blueswin provides custom micro end mills and ultra-fine cutters for components like smartphone frames, metal casings, PCB housings, display modules, and polarizer films. Our tools are manufactured with strict concentricity control and low runout to ensure burr-free edges, tight fitting tolerances, and smooth finishes.

Whether you’re machining magnesium frames or laser-cutting optical layers, our tooling supports high-speed production lines with low scrap rates and minimal maintenance—ideal for OEMs and contract manufacturers alike.

General Industrial & Tooling Applications

Versatile performance for a wide range of machining tasks

- Custom cutting tools for industrial equipment

- Wear-resistant tools for high-volume production environments

- Precision components for automation, robotics, and machinery

Not every production challenge fits standard tooling. That’s where Blueswin’s custom end mills shine. We develop tools for industrial equipment parts, jigs, fixtures, dies, mold cavities, and components across robotics, automation, and energy sectors. Whether you require non-standard flute lengths, custom angles, special coatings, or hybrid geometries, we design for your specific workflow and machining conditions.

From wear-resistant coatings for high-volume production to ultra-fine finishing tools for complex contours, our capabilities give you the flexibility to tackle diverse materials—steel, copper, plastics, or hardened alloys—with consistent quality and confidence.