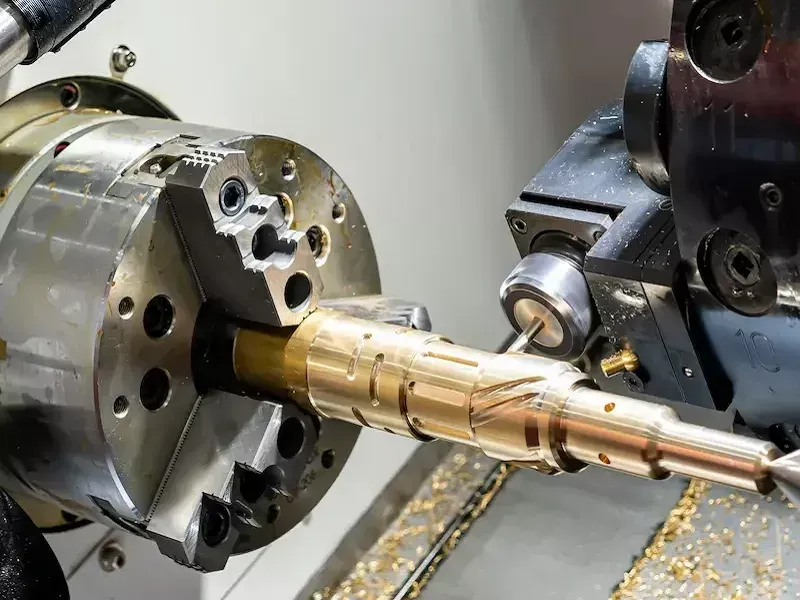

CNC Milling Services, Built for Precision

From simple 3-axis jobs to complex 5-axis components, Blueswin delivers high-accuracy CNC milling with short lead times and consistent quality.

At Blueswin, we combine over 10 years of toolmaking expertise with large-scale CNC manufacturing. Located in a 20,000㎡ industrial park and equipped with 500+ CNC machines, we support a wide range of industries with precision-milled parts.

CNC Milling Services for Custom Parts

3-Axis CNC Milling

With 3-axis CNC milling, precision meets affordability. It’s your go-to for simple parts that still demand accuracy.

4-Axis CNC Milling

Think of a design, and 4-axis milling can probably make it. Multi-sided machining just got a whole lot simpler.

5-Axis CNC Milling

For those complex and intricate parts, 5-axis milling is the master key. Bring your most ambitious designs to life.

Seamless Solutions for Every Product

Development Milestone

Our customization process ensures that you will be satisfied at every step.

Submit Files

Upload your CAD drawing (.STEP / .STL / PDF) and project specs. We also accept 2D prints or technical sketches.

DFM & Quote

Our engineers review your design for manufacturability and respond with a quote and timeline within 24 hours.

Process Planning

We handle toolpath programming, fixture design, and machining strategy—tailored to your material and geometry.

CNC Machining

Parts are precision-machined in-house using 3/4/5-axis systems. Tolerances up to ±0.005mm available.

Surface Finish

Optional post-processing includes anodizing, polishing, sandblasting, and laser marking.

Inspection & Delivery

Final parts are fully inspected, packaged, and shipped with optional QC reports and certificates.

Frequently Asked Questions

What types of CNC milling do you offer?

We offer 3-axis, 4-axis, and 5-axis CNC milling services. Whether your part requires simple flat surfaces or complex multi-angle features, we have the right machining capabilities to meet your requirements.

What materials can you machine?

We work with a wide range of metals and plastics, including aluminum, stainless steel, copper, titanium, brass, POM, PTFE, PEEK, and CFRP. If your material isn’t listed, feel free to contact us—we may still be able to support it.

What tolerances can you achieve?

Our standard machining tolerance is ±0.01mm, with high-precision options down to ±0.005mm available upon request, depending on part geometry and material.

Do you provide prototyping or small batch services?

Yes. We support rapid prototyping as well as small-to-medium batch runs. Whether you need 1 piece or 1,000 pieces, we can tailor our process to your production needs.

Can you assist with design optimization or DFM?

Absolutely. Our engineering team offers DFM (Design for Manufacturability) consultation to ensure your design is optimized for both cost and performance. We’ll provide feedback before production to avoid potential issues.

What’s the typical lead time for CNC machining?

Prototype parts can typically be delivered in 5–7 working days. Lead time for batch production depends on part complexity and quantity, but we always aim to meet your project deadlines.

Do you offer quality inspection reports?

Yes. Every batch is inspected according to ISO-level standards, and we can provide full dimensional inspection reports, surface finish documentation, and material certificates upon request.